Fuente El Economista

Canadá, tercer mayor emisor de IED hacia Querétaro

Es la séptima entidad federativa con más recepción de inversión canadiense en el país, al sumar 2,062.0 millones de dólares entre 1999 y el año pasado.

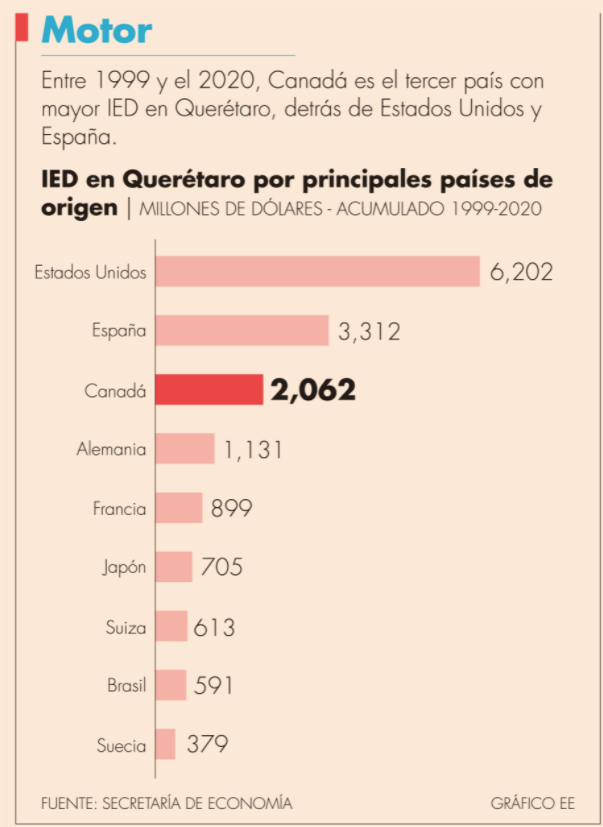

Querétaro, Qro. Canadá se posiciona como el tercer mayor emisor de Inversión Extranjera Directa (IED) hacia Querétaro, acumulando 2,062.0 millones de dólares desde 1999 al 2020, detallan registros de la Secretaría de Economía.

La IED canadiense se encuentra sólo por debajo de la inversión proveniente de Estados Unidos y de España, que en ese periodo aportaron 6,202.3 y 3,311.7 millones de dólares, respectivamente.

Frente al impacto por la pandemia, en el 2020 la entidad recibió 43.7 millones de dólares con origen en Canadá, esta cifra significa una baja de 50.3% anual.

Del 2008 al 2010, el estado reportó los montos anuales más elevados de inversión canadiense; 233.5 millones de dólares en el 2008, 213.8 millones en el 2009 y 267.6 millones en el 2010. En ese trienio, la IED canadiense sumó 714.9 millones de dólares, que representan 34.7% del total acumulado desde 1999 al 2020.

Con cifras acumuladas, Querétaro es el séptimo con mayor recepción de IED canadiense en el país, al sumar 2,062.0 millones de dólares de 1999 al 2020, por debajo Zacatecas (6,594.7 millones), Ciudad de México (5,852.6), Chihuahua (4,173.6), Coahuila (3,282.4), Sinaloa (3,222.1) y Guerrero (2,790.2).

Presencia de firmas

Bombardier es una de las firmas canadienses instaladas en la entidad, forjando un amplio historial de operaciones en el centro del país; en este contexto, la firma aeroespacial cumple 15 años de instalarse en Querétaro.

Desde esta ubicación fabrica componentes estructurales clave para los jets de negocios líderes de la compañía, incluido el fuselaje trasero de todas las aeronaves Global.

En el 2005 Bombardier Aerospace anunció el establecimiento de un centro manufacturero de clase mundial en Querétaro, el cual emprenderían con una inversión de 200 millones de dólares. En el 2006 inició actividad con un centro de manufactura temporal en el Parque Industrial El Marqués.

Para el 2008, anunció una inversión de 250 millones de dólares para llevar a cabo la manufactura del fuselaje, ensamble de las alas, estabilizadores horizontales y verticales, así como la fabricación e instalación de arneses eléctricos para la aeronave Learjet 85, desde sus instalaciones de Querétaro.

En el 2011 anunció una nueva inversión de 50 millones de dólares en la planta de Querétaro para apoyar la fabricación del fuselaje trasero de sus nuevas aeronaves de negocios Global 7000 y Global 8000.

En México, Bombardier se centra en producir estructuras metálicas, arneses eléctricos y fabricar piezas a base de materiales compuestos.